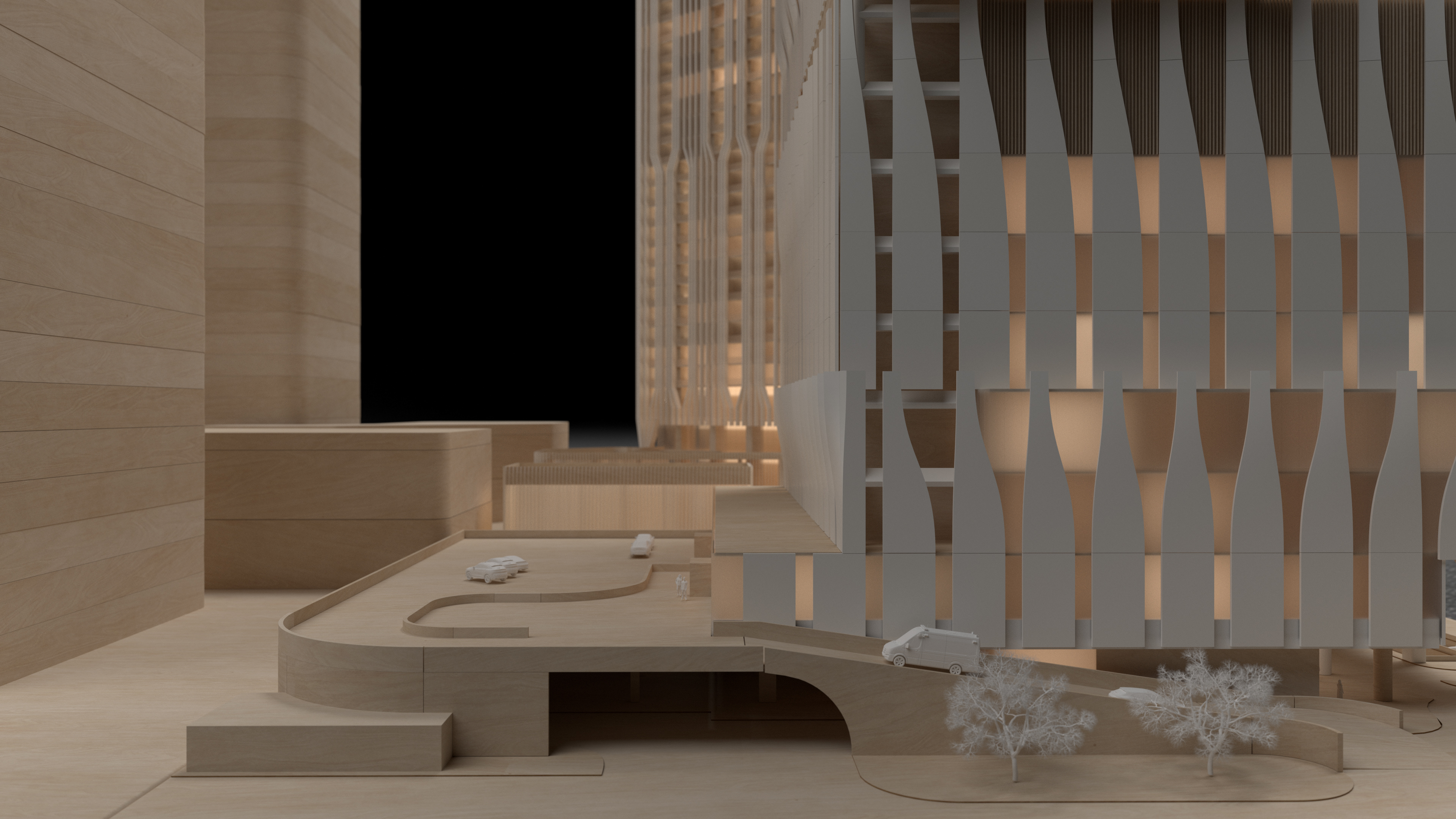

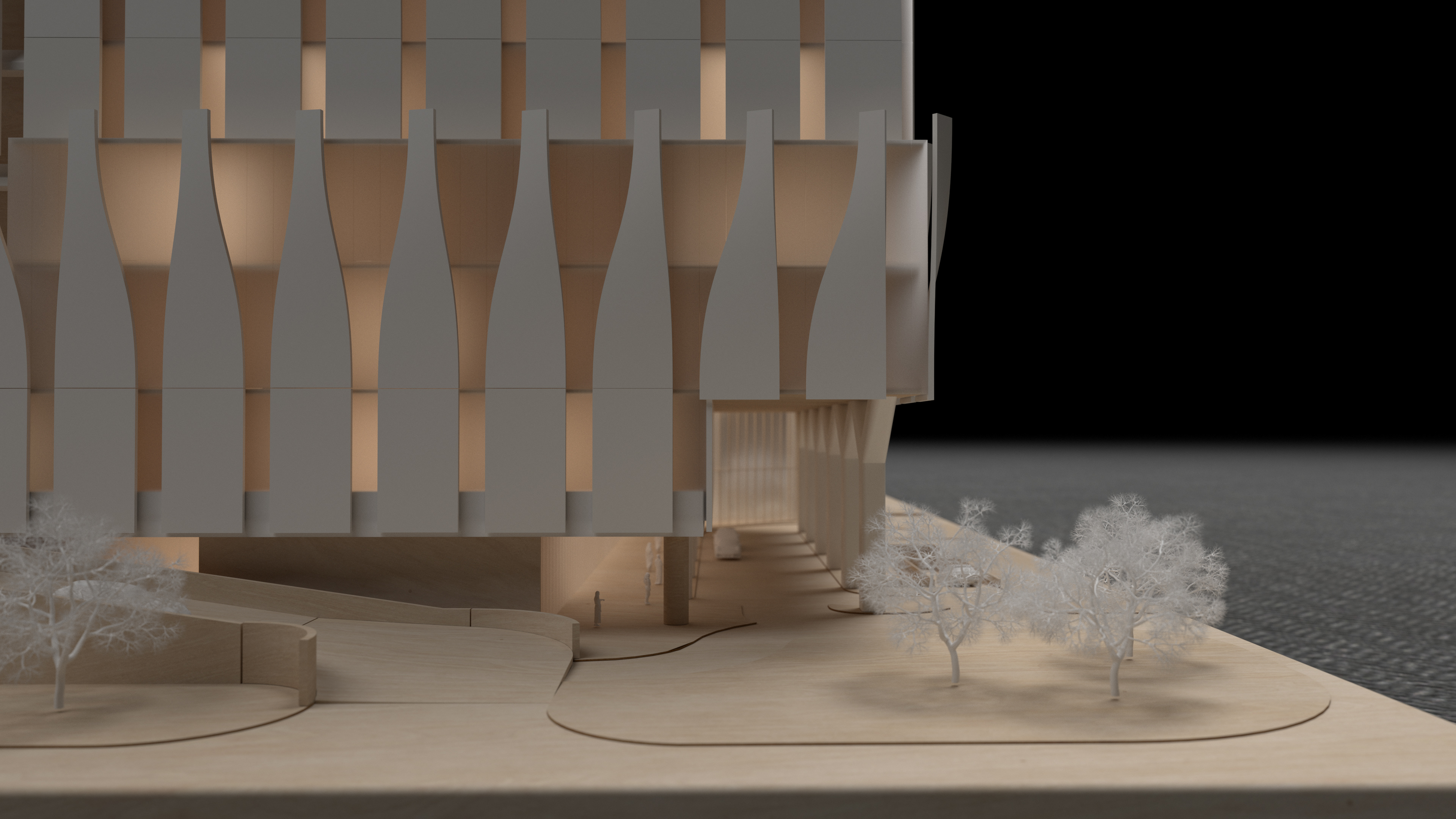

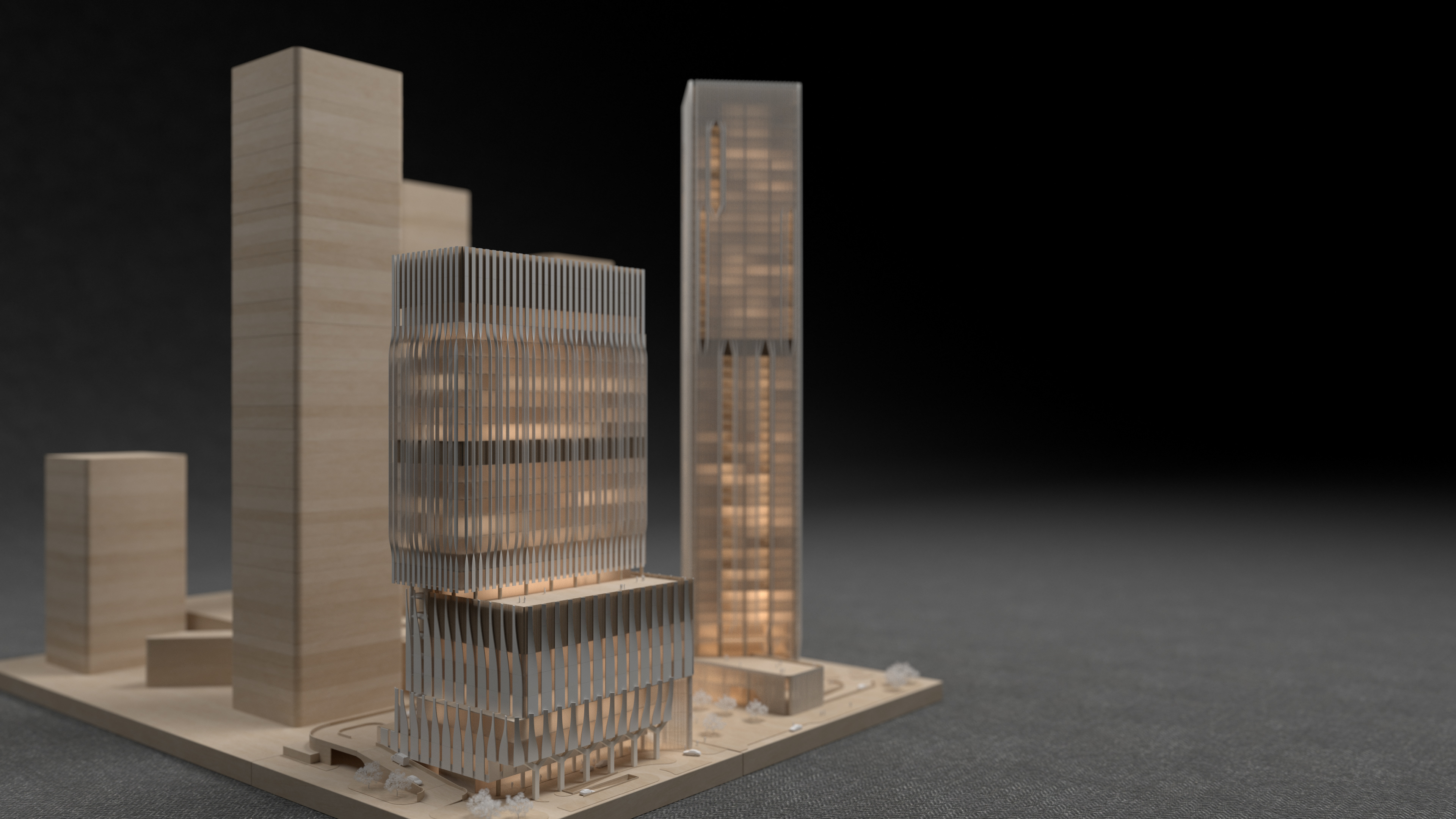

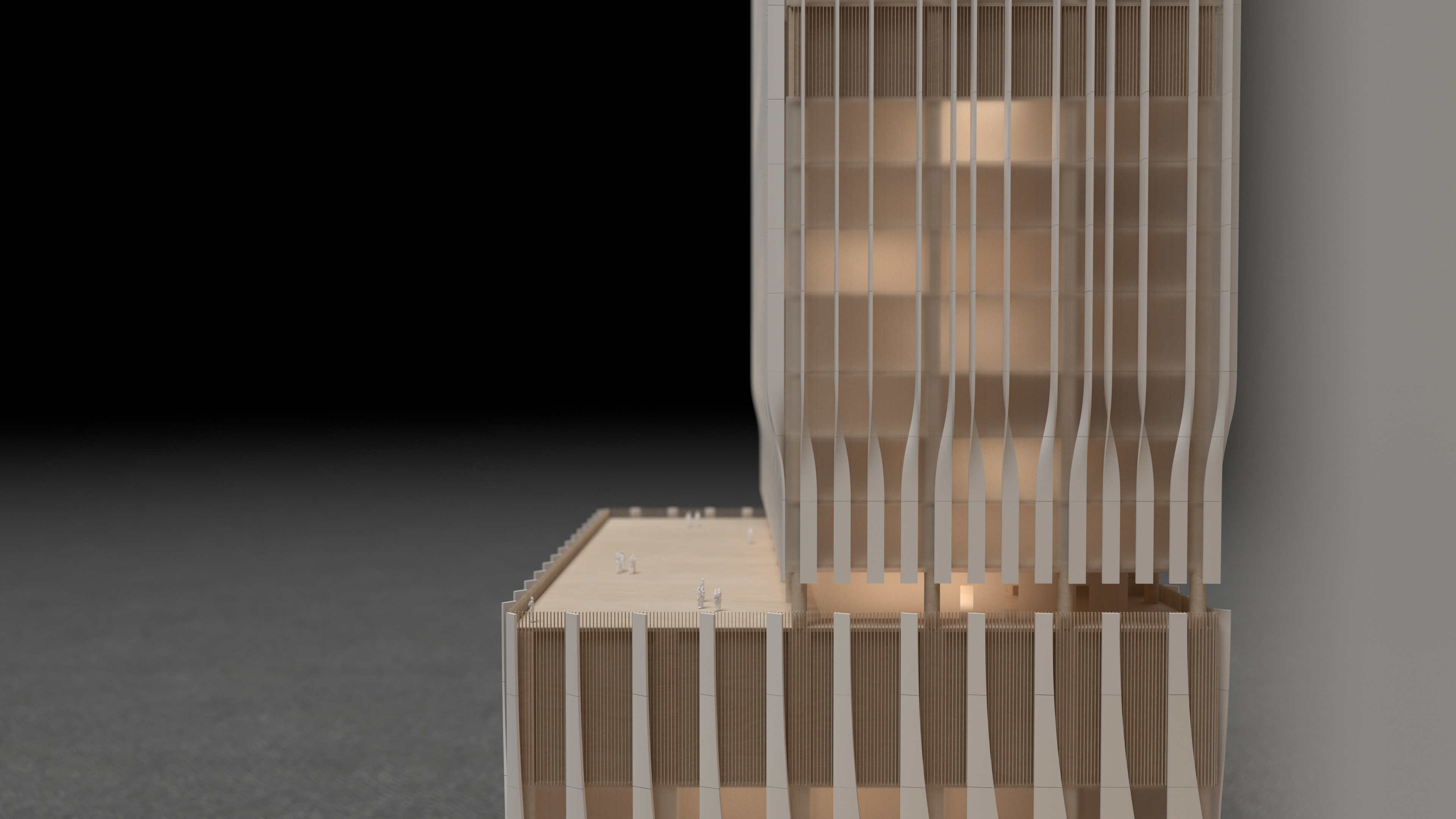

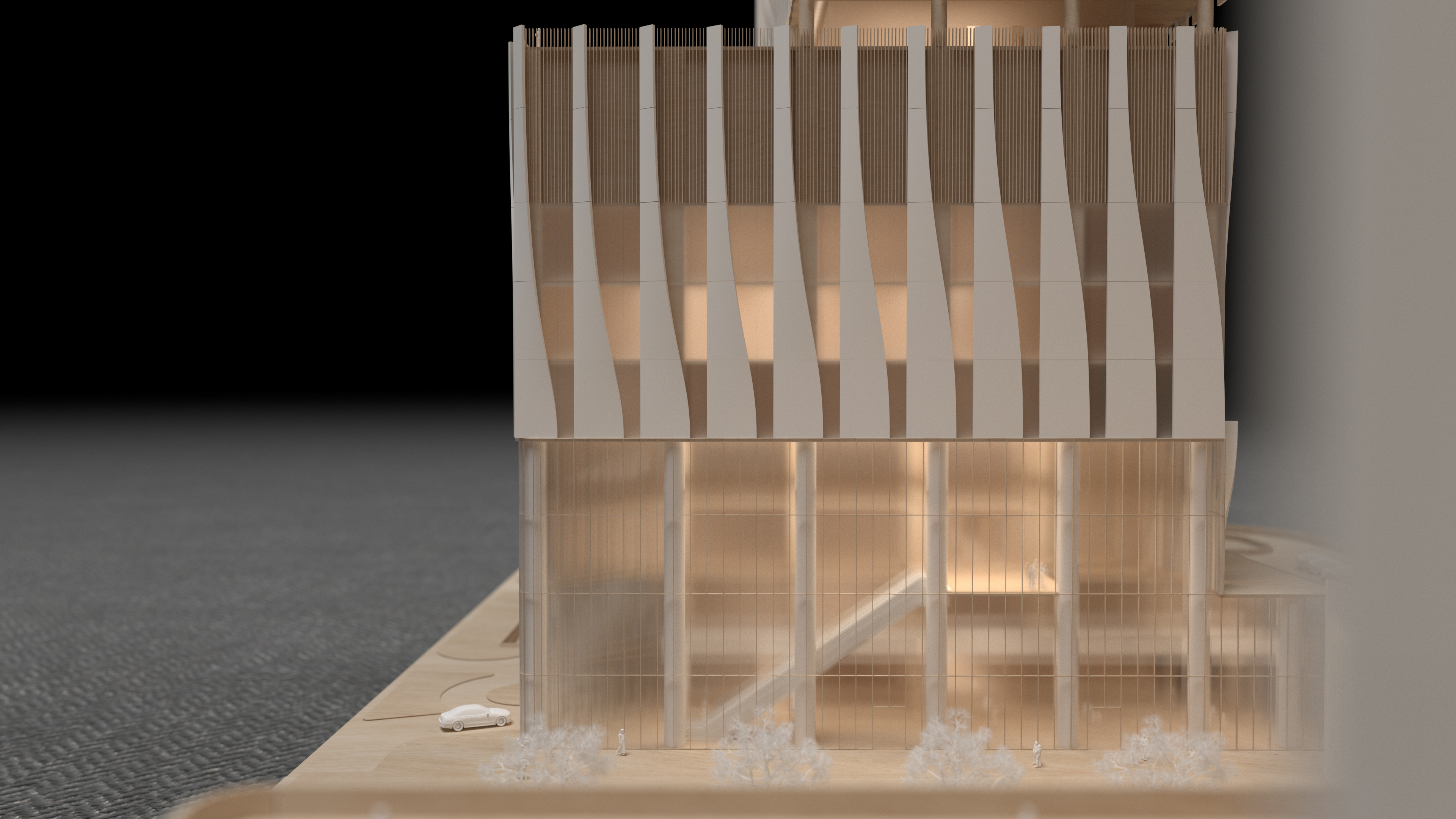

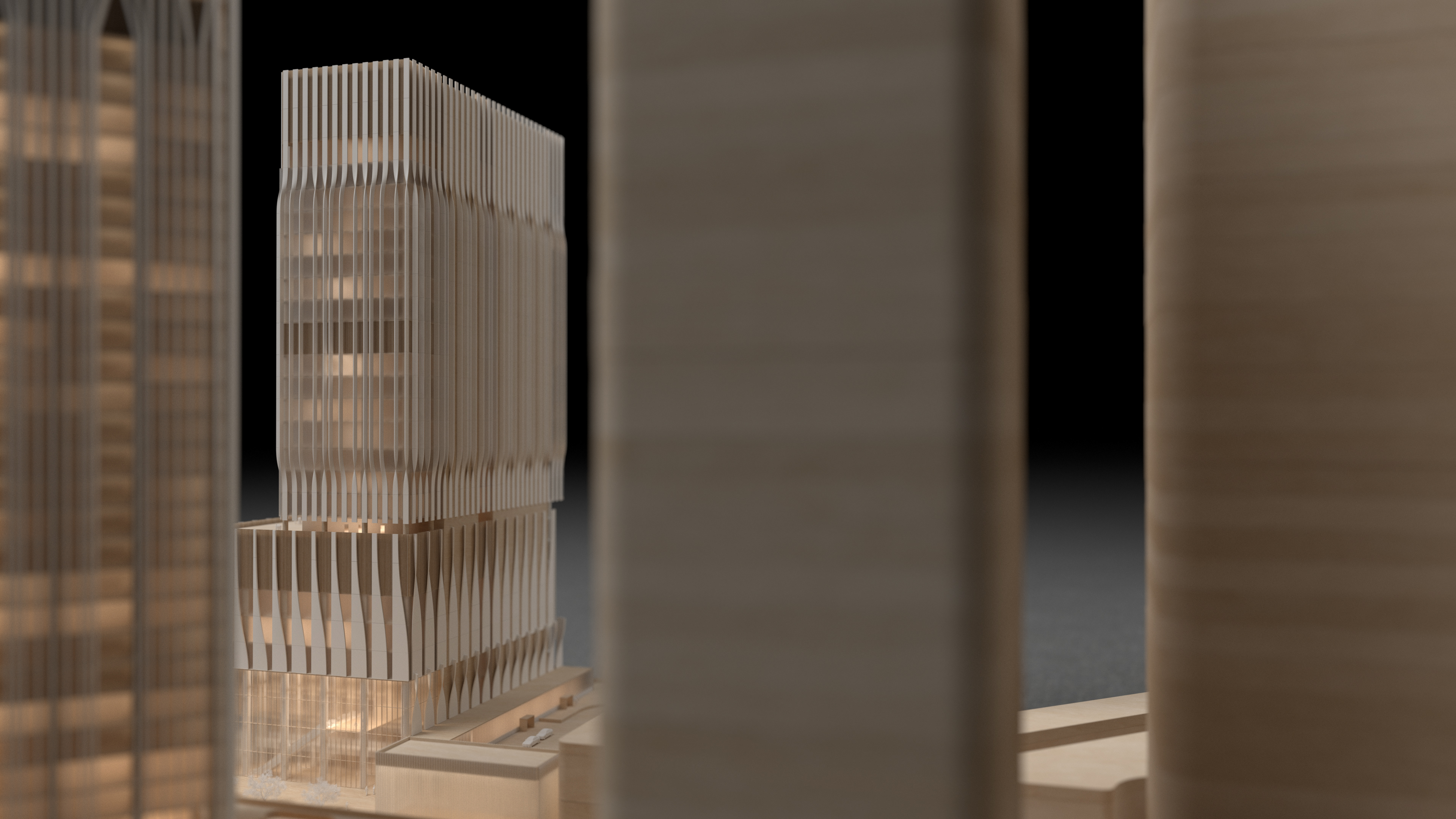

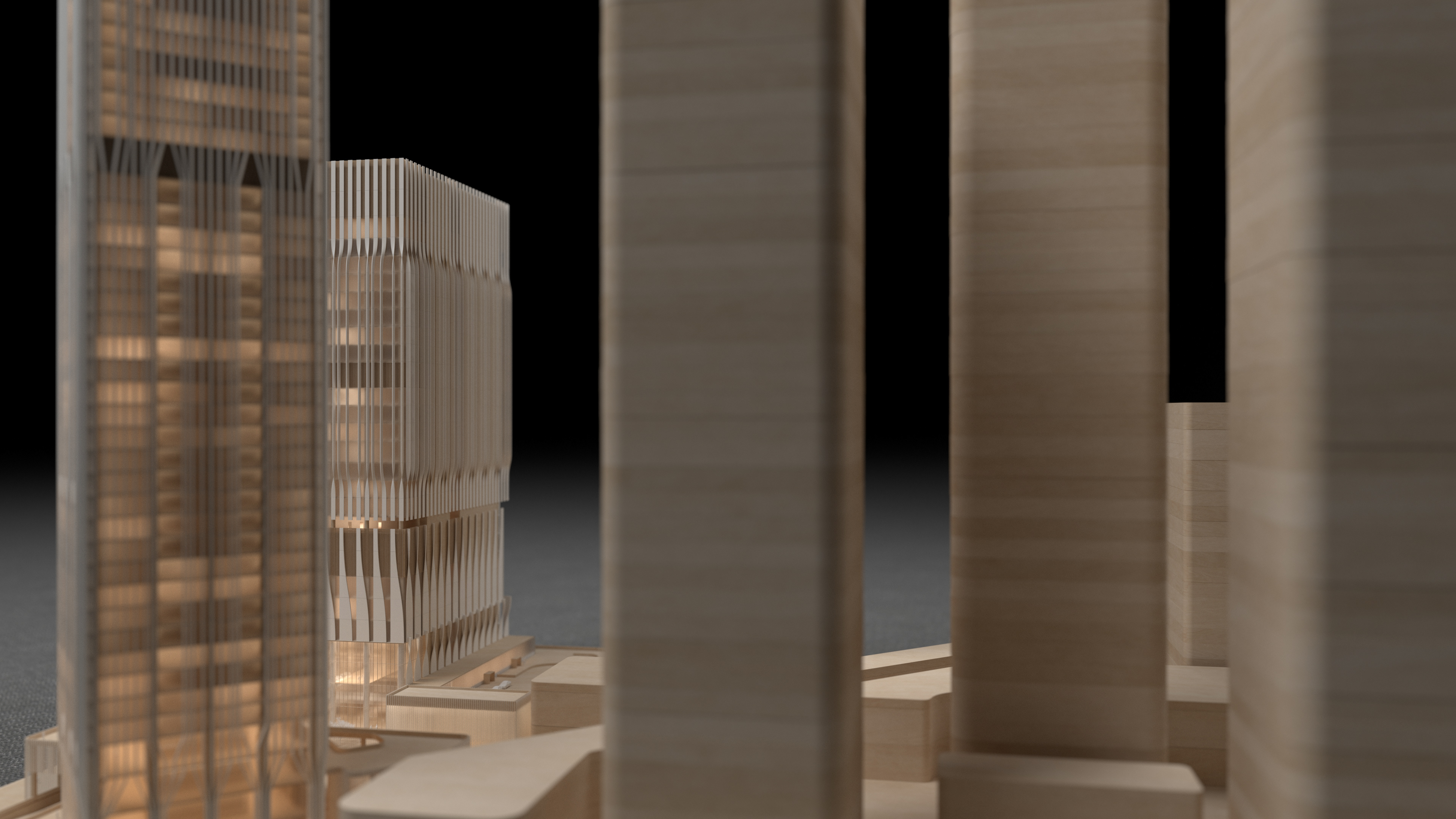

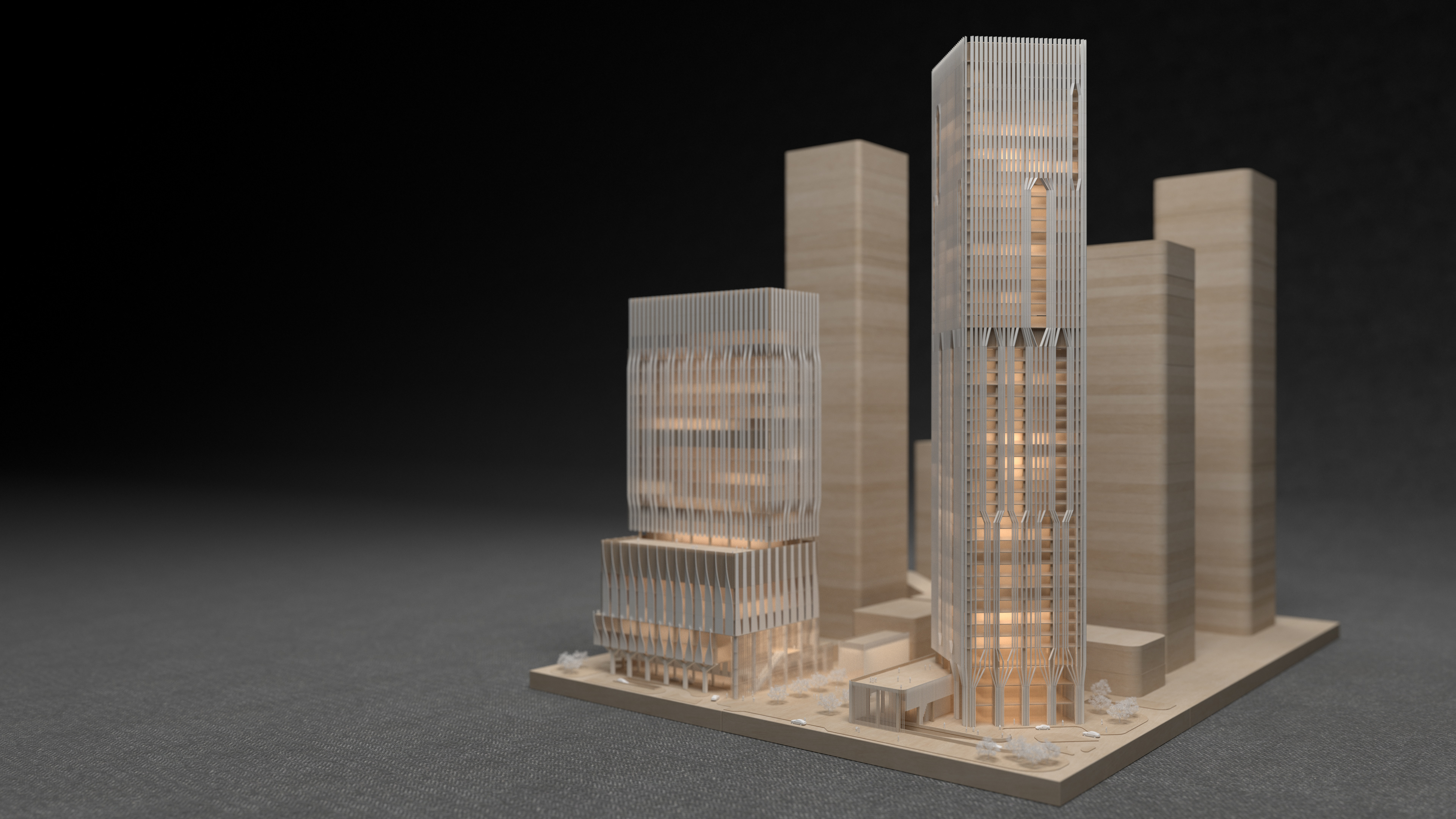

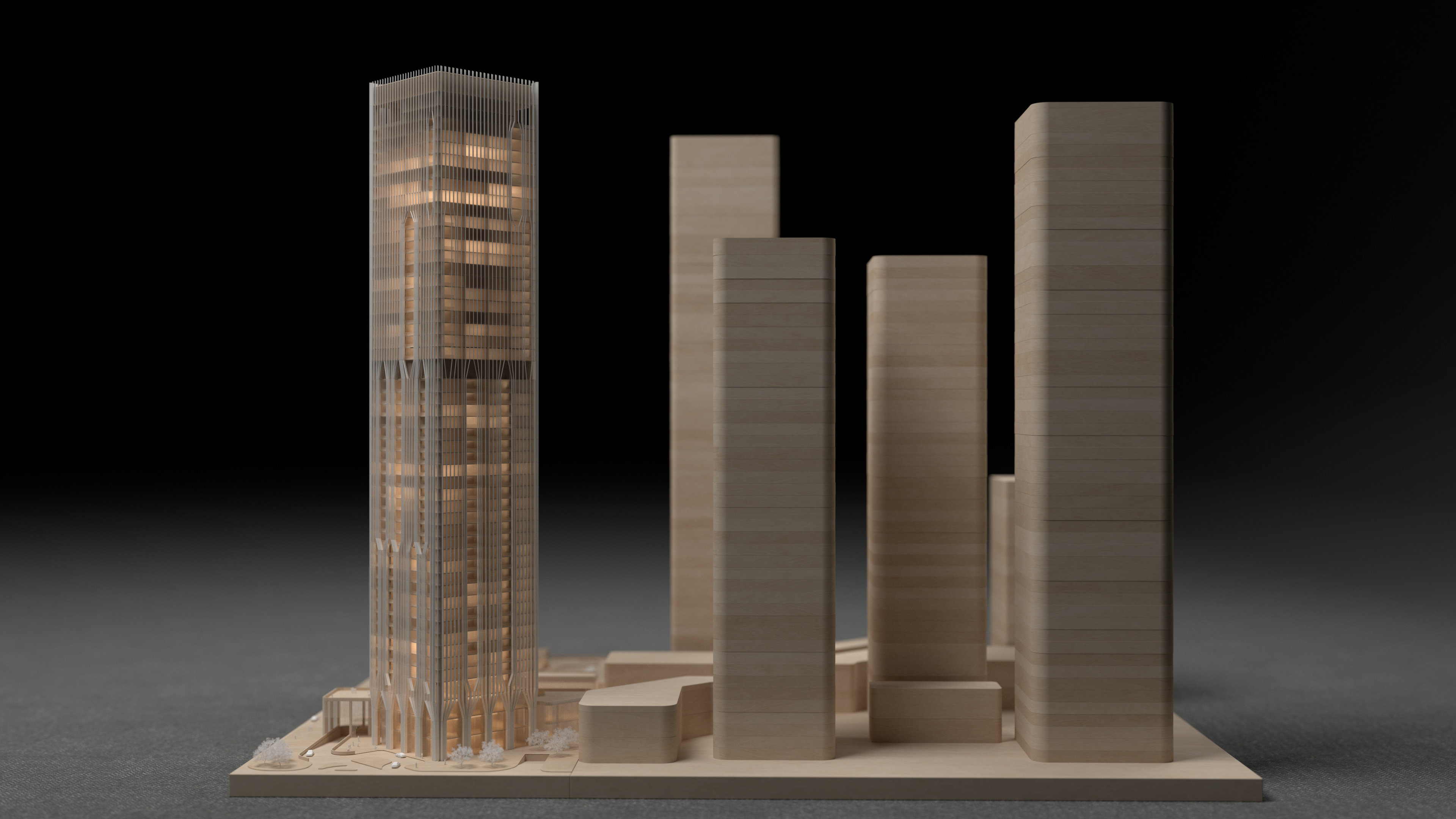

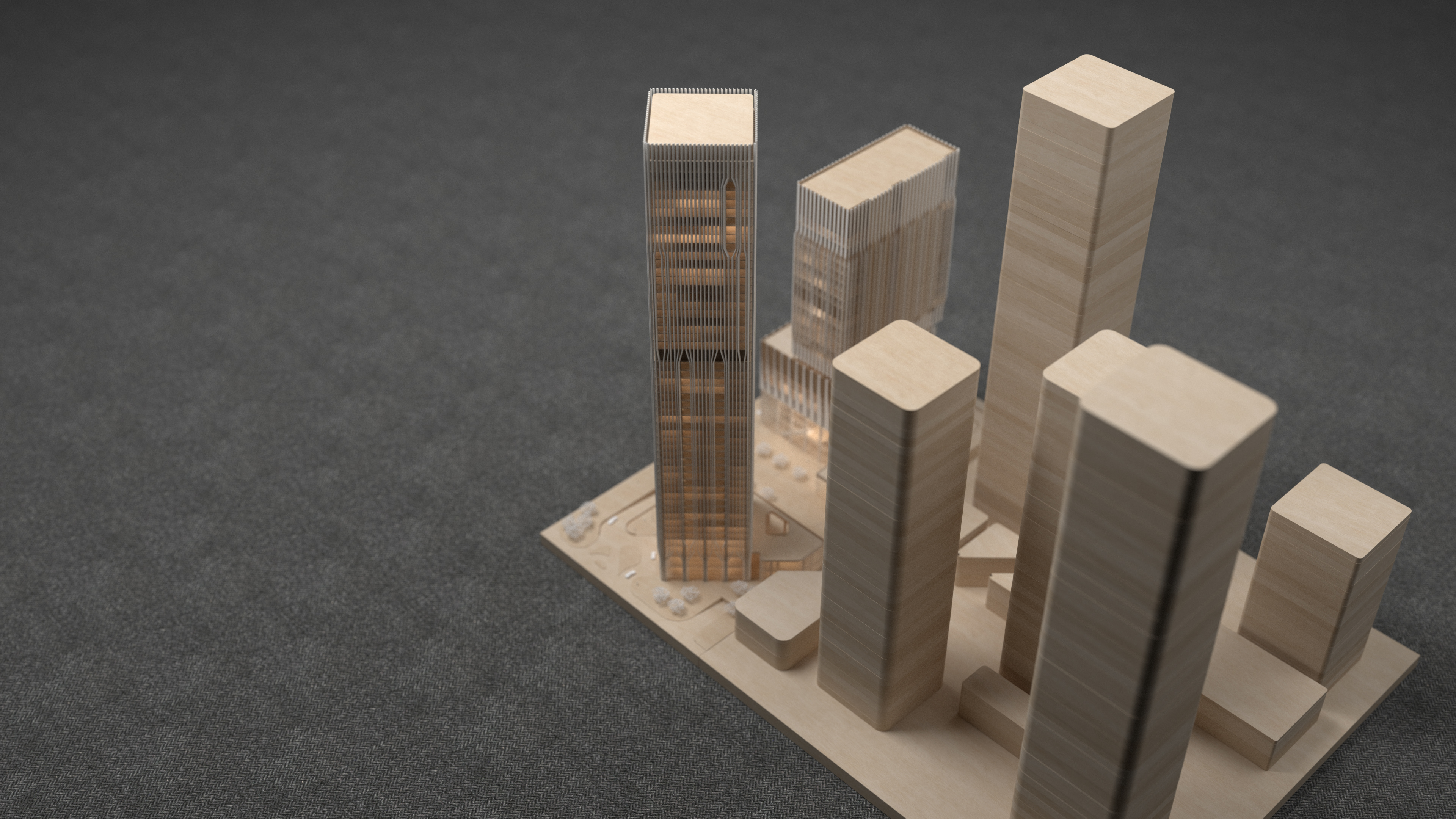

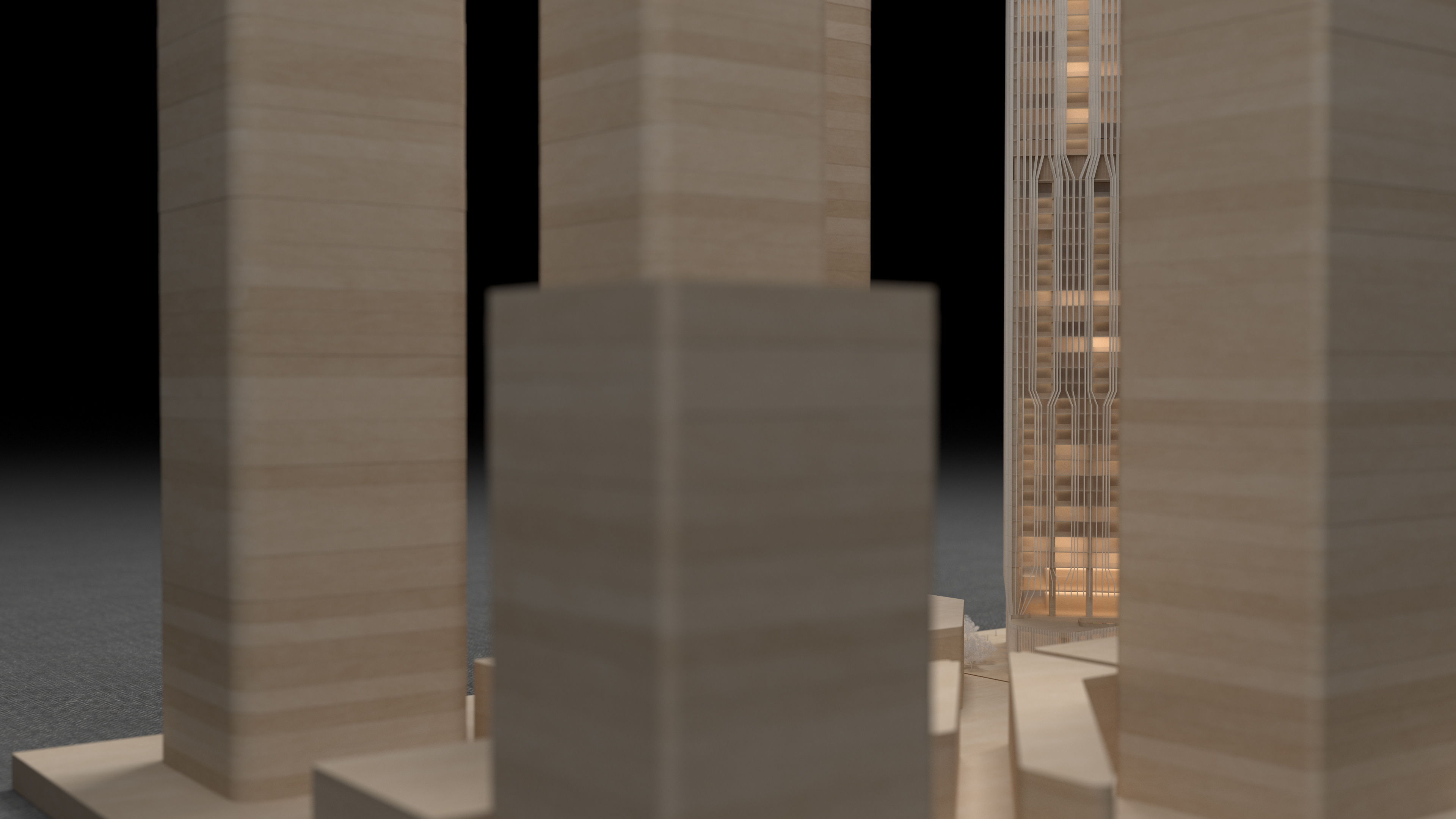

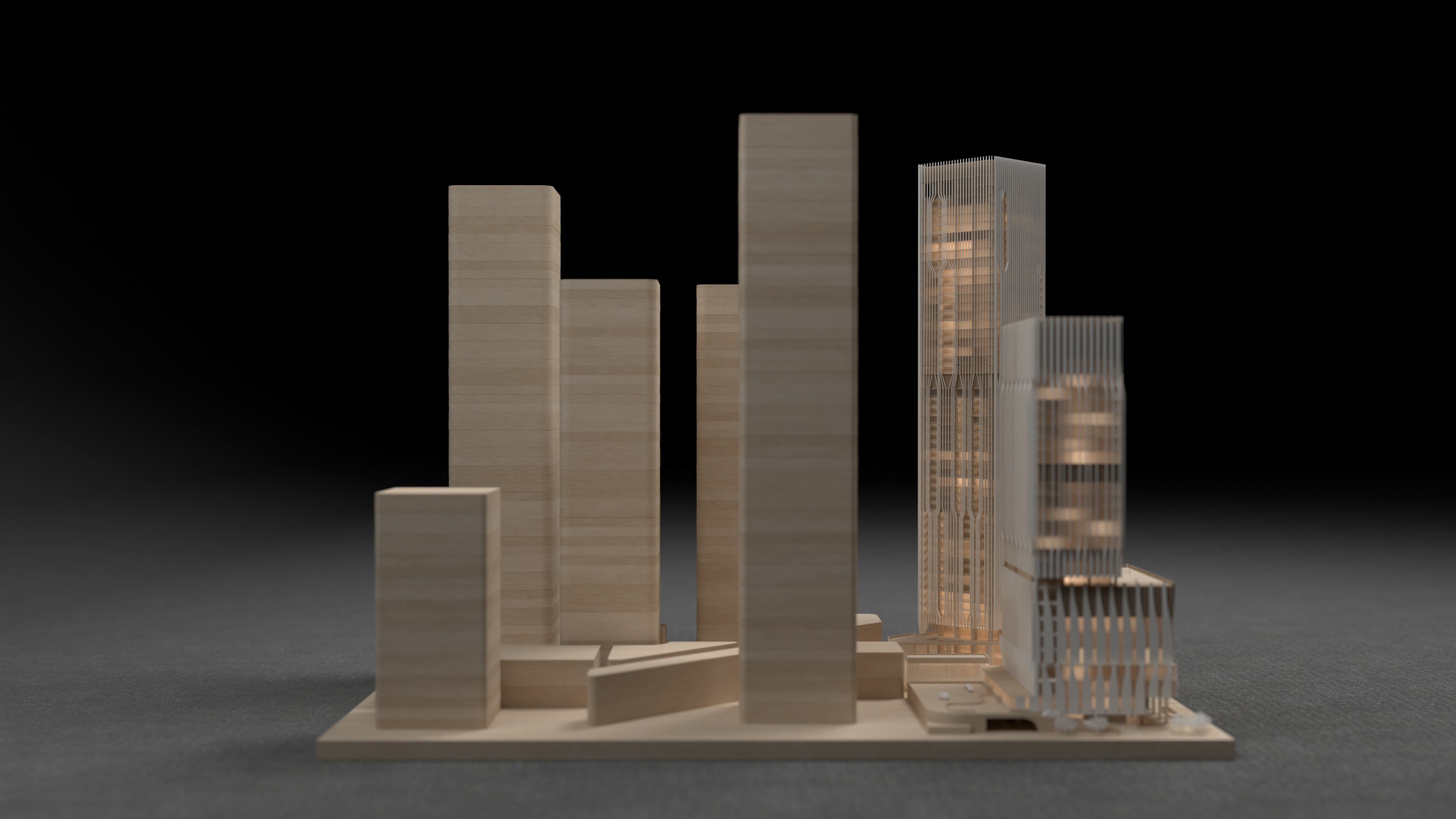

This development form a landmark development in downtown Riyadh. The 103,000 GSM, 27-story, 186-bed hospital seamlessly integrates advanced medical care with refined design, optimizing functionality and patient experience. Organized into a podium and tower, the hospital features key medical services on lower levels and inpatient care above, connected by a Sky Lobby focused on wellness. The design maximizes natural light and operational efficiency. Adjacent, the residential tower anchors the retail corridor with a strategic 45-degree rotation, offering uninterrupted views and enhancing the site's urban fabric.

This project fully integrates parametric design and computational design throughout the entire architectural workflow, from initial form exploration to performance-driven optimization and final fabrication. In the early stages, parametric modeling was used to explore the building’s scale and form, allowing for rapid generation and evaluation of different massing options through rule-based adjustments. During the mid-stage, computational design was combined with environmental data to optimize the building’s façade based on solar exposure and view analysis. This algorithm-driven approach ensured a balance between performance and aesthetics. In the final stage, parametric modeling facilitated façade modifications and streamlined the manufacturing process. The model could quickly adapt to design changes and directly provide precise data for fabrication, improving production efficiency and minimizing errors by delivering standardized geometric information to the factory. This process demonstrates the deep integration of parametric and computational design throughout the architectural lifecycle, reinforcing design precision and enhancing the connection between design and fabrication.

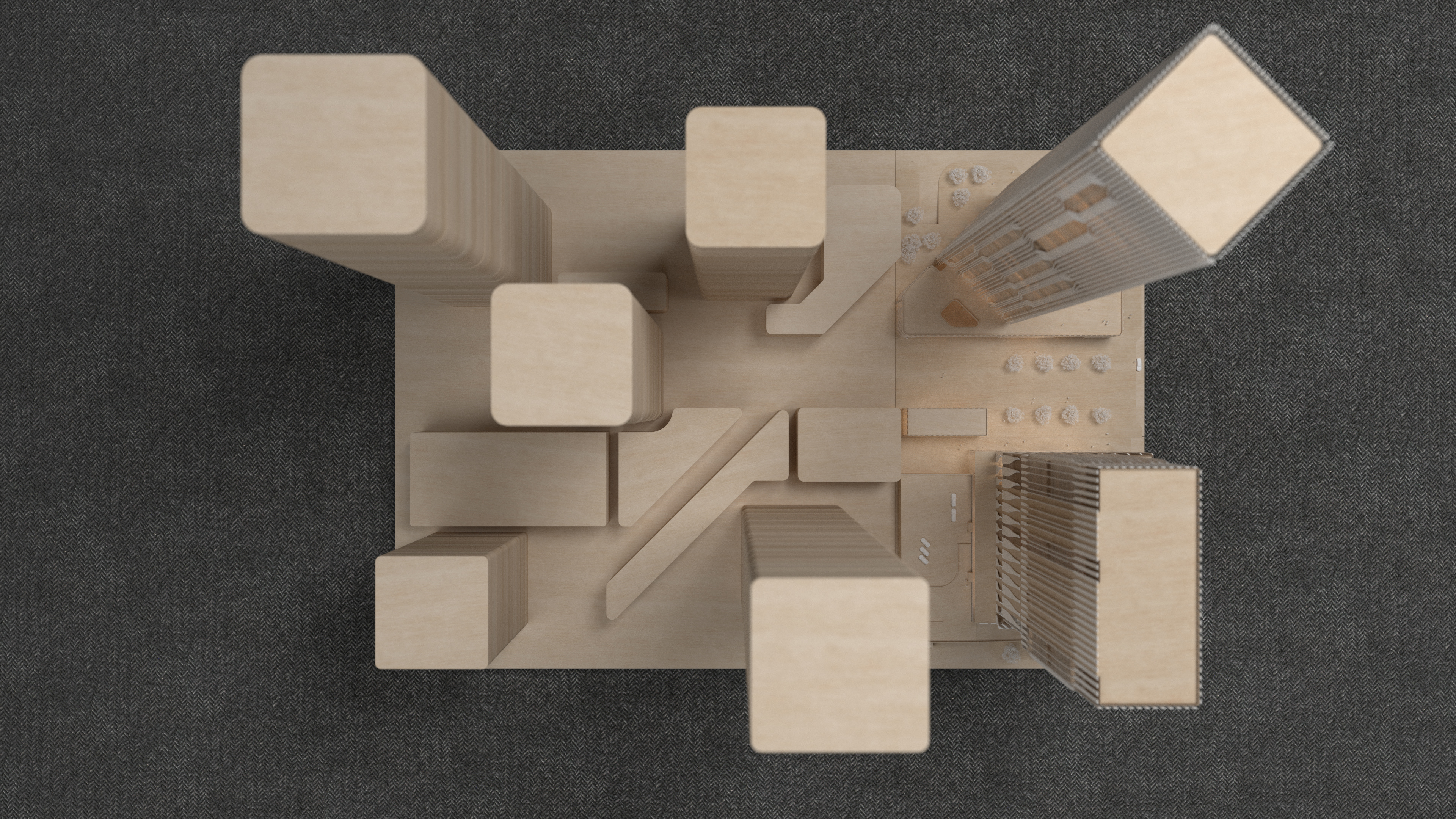

In the first stage, parametric modeling was used to rapidly generate and optimize the building massing to meet site constraints, regulatory requirements, and functional needs. By dynamically adjusting parameters such as site coverage, setbacks, floor heights, and volume positioning, the building scale and layout were iterated efficiently across multiple possibilities. The system automatically calculated the optimal number of floors based on key data like FAR (Floor Area Ratio) and GFA (Gross Floor Area) while refining the spatial relationship between the hospital and residential towers. Ultimately, parametric modeling not only enhanced design efficiency but also laid the foundation for solar analysis, view optimization, and seamless integration with fabrication.

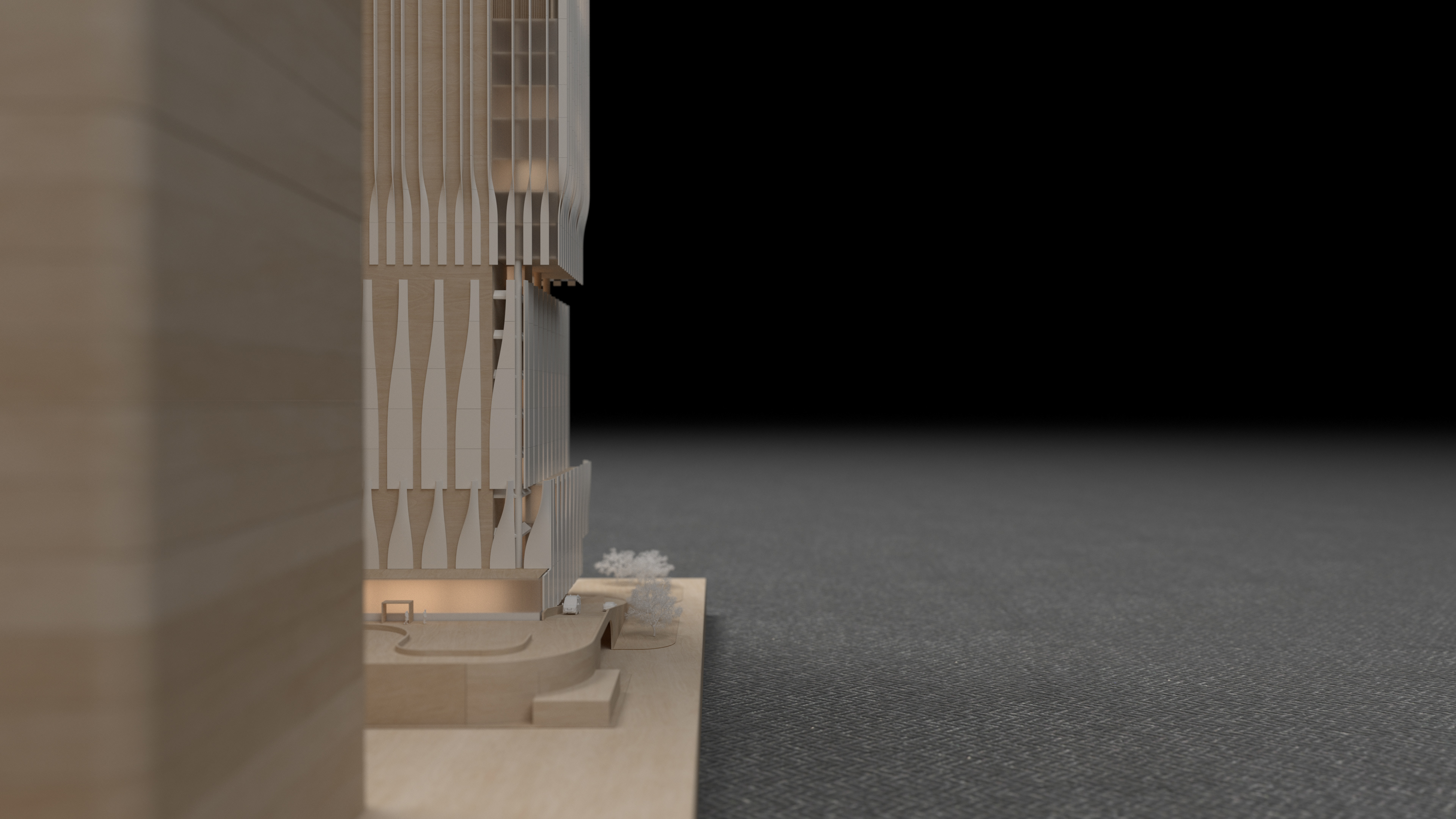

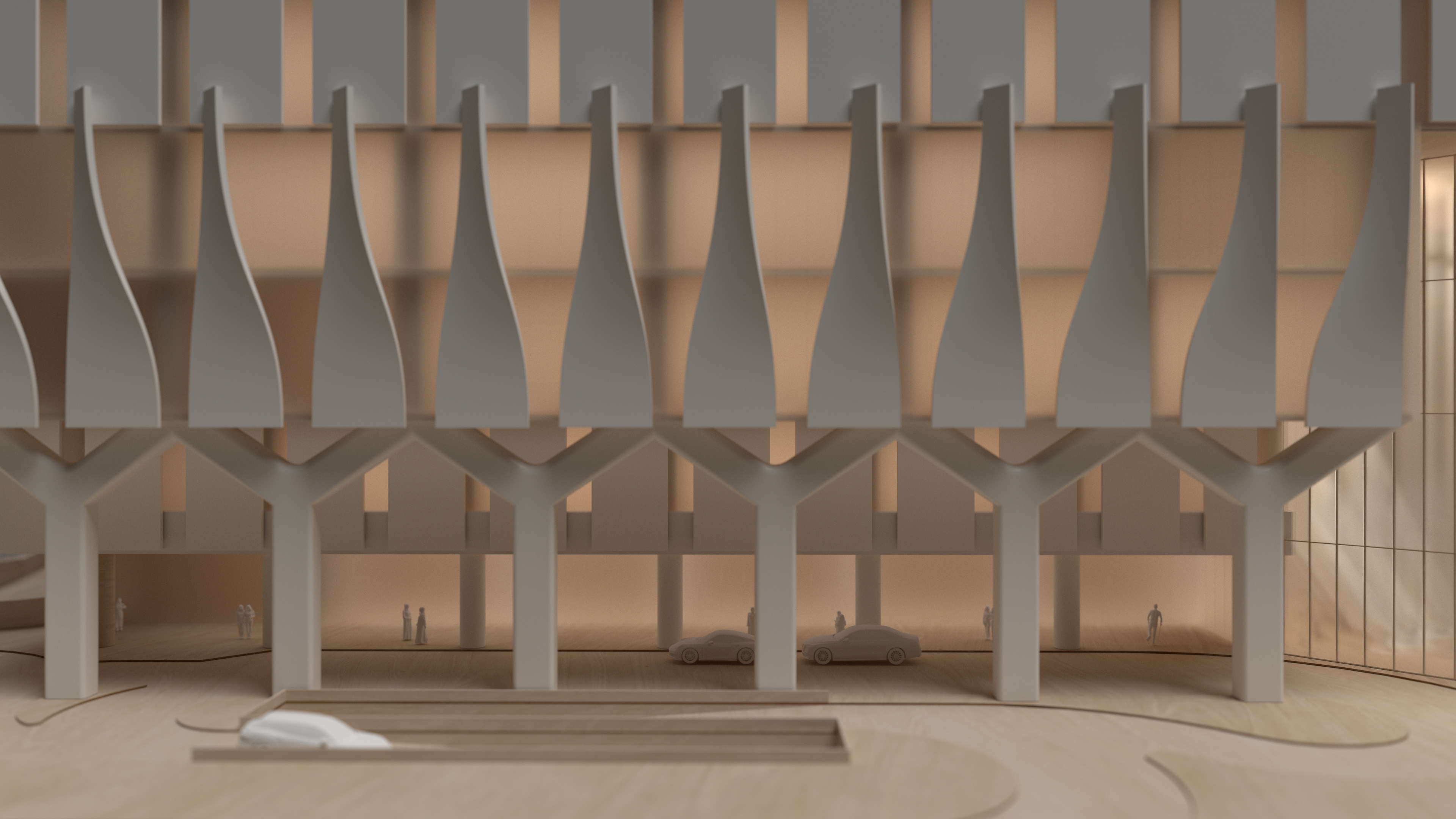

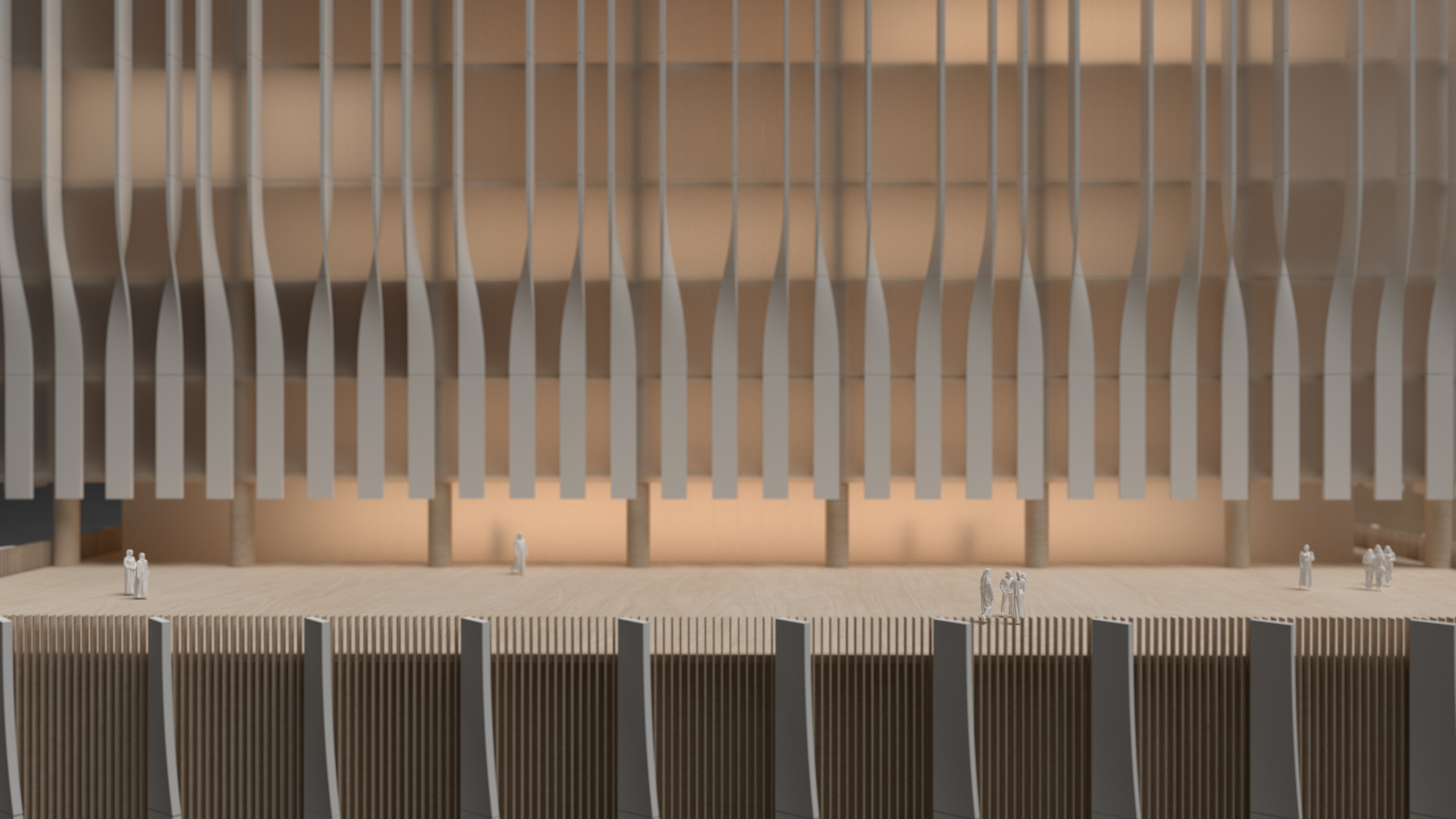

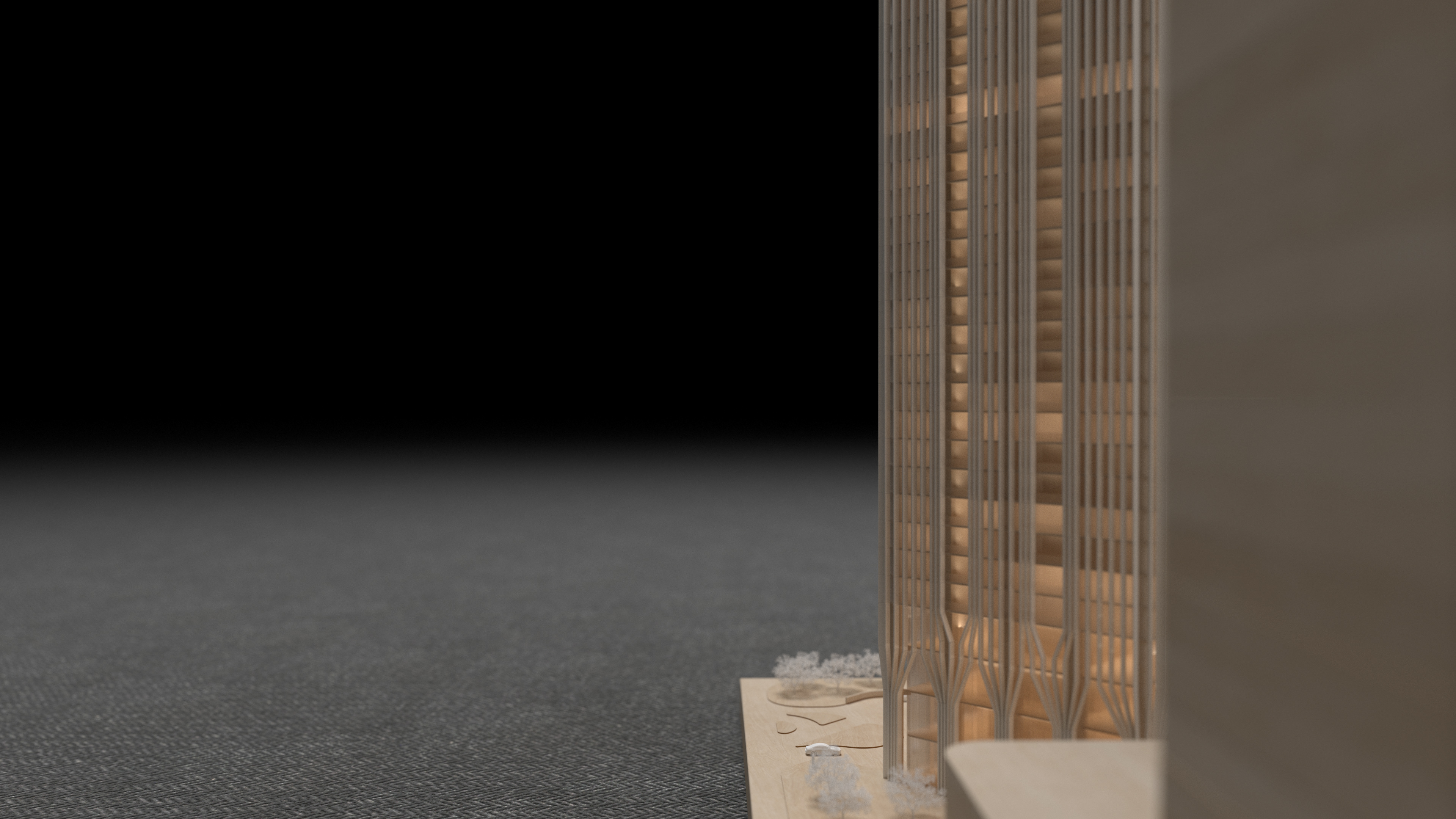

In the mid-stage, computational design was utilized to optimize the building façade, driven by solar exposure, view quality, and environmental data to generate a high-performance envelope. By integrating parameters such as solar radiation, wind speed, and humidity, the system automatically evaluated different façade configurations and used algorithms to analyze light transmission, shading efficiency, and view quality to determine the optimal geometric form. Parametric modeling ensured design flexibility, allowing real-time adjustments to panel angles, spacing, and shapes while continuously refining results, achieving a balance between aesthetics, performance, and environmental responsiveness.

In the final stage, parametric modeling was utilized to refine architectural details and provide precise data for manufacturing and construction. The optimized façade geometry was directly exported to the fabrication process, ensuring that each panel’s dimensions, angles, and connections met production requirements, reducing errors and improving construction efficiency. The parametric model also allowed for rapid adjustments in response to design changes, maintaining flexibility in the later stages of the project. Additionally, the final dataset was used for construction documentation, enabling a seamless transition from digital design to physical realization.

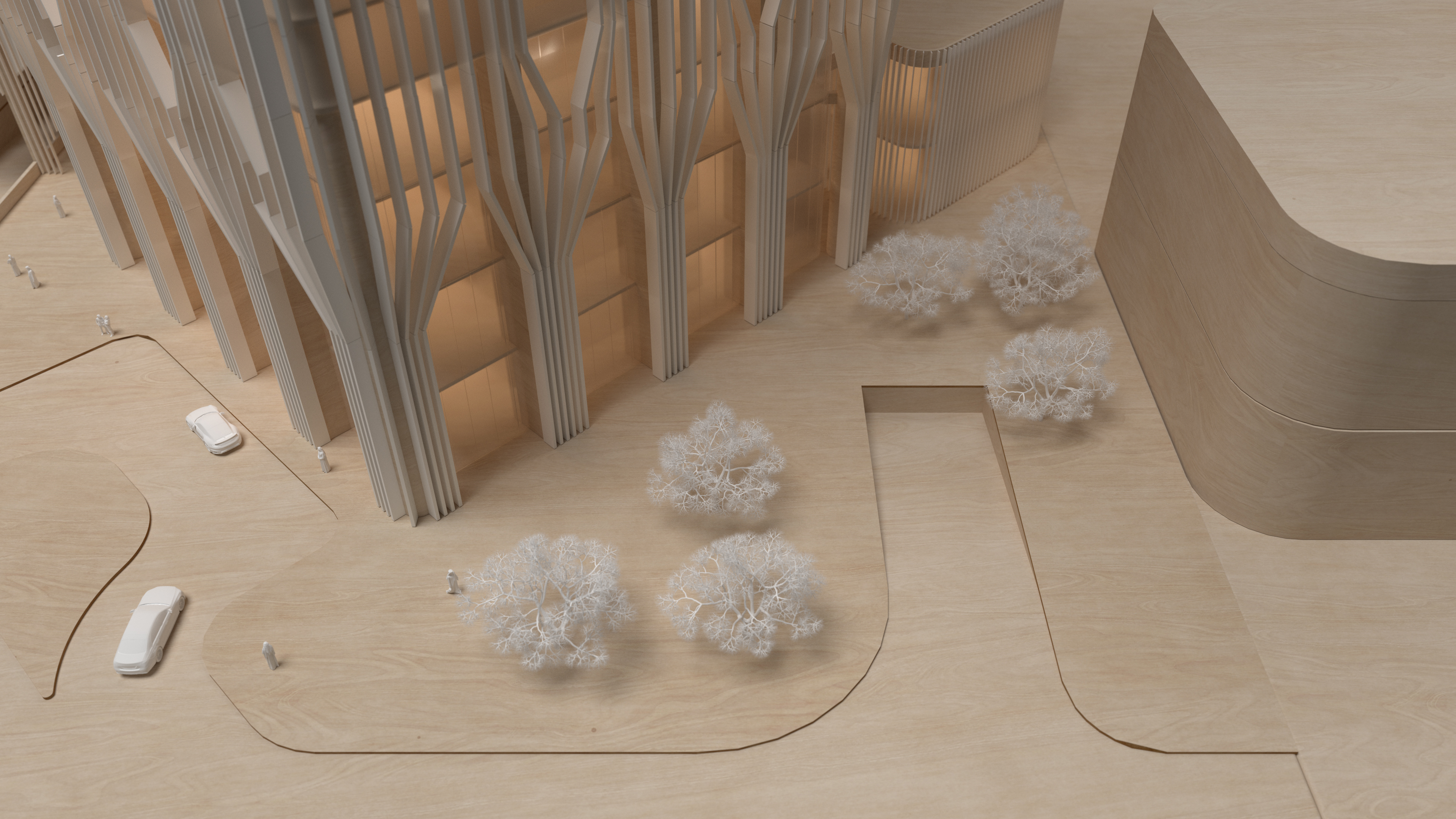

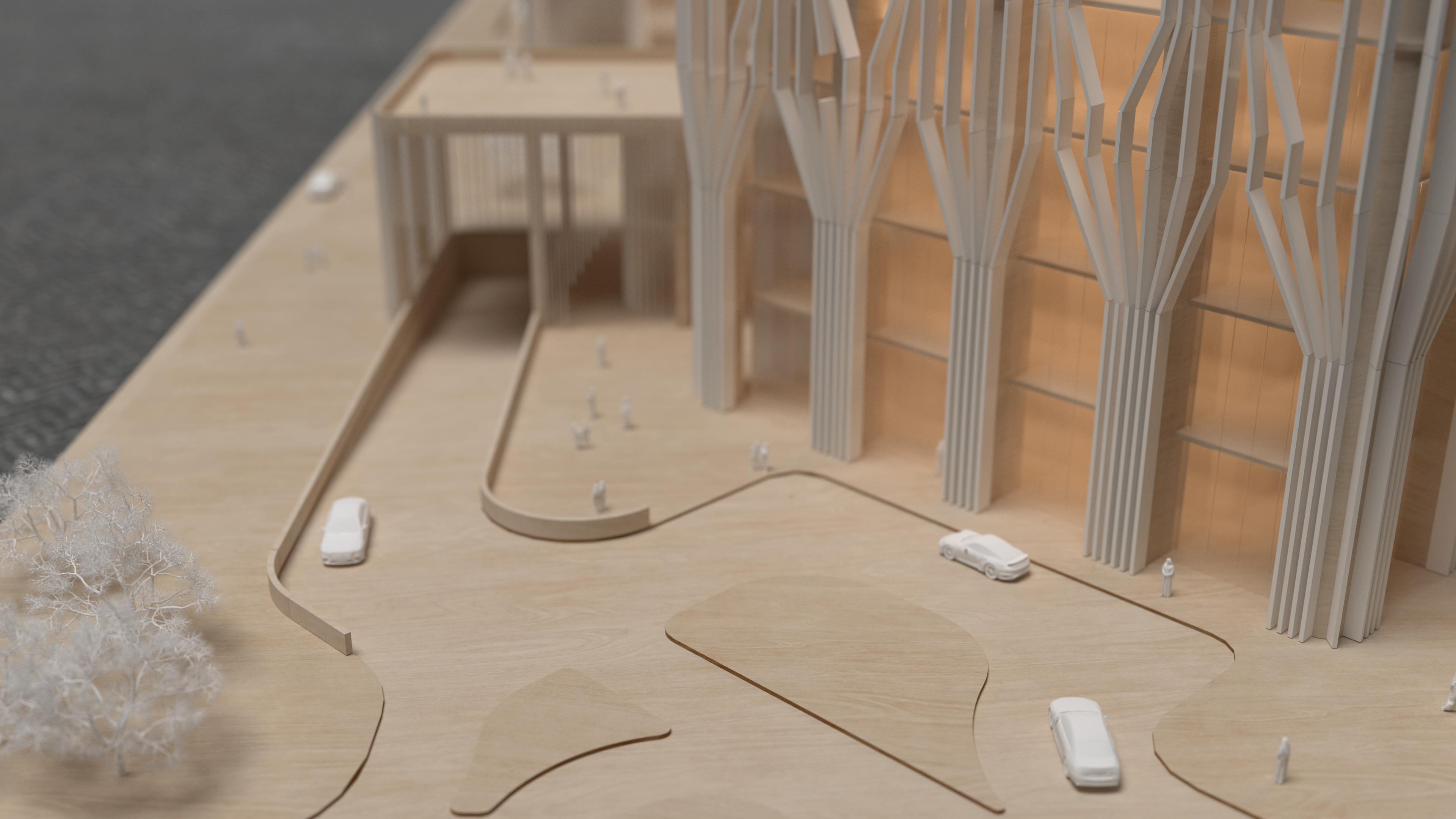

In the final presentation stage, a self-developed wooden model-style geometry generation tool was combined with a parametric workflow to achieve video rendering with a distinctive visual style. This tool converts complex architectural geometry into a wooden model-like aesthetic, controlling parameters such as panel textures, simplification levels, and edge representation to produce an architectural expression that captures the tactile quality of handcrafted models.